Invention by Design;

How Engineers Get from Thought to Thing

Henry Petroski | 1996

[Excerpt] ...Why do manufacturers risk producing products inferior to what already exists? A book on "successful product design" provides some insight. Written by a former director of design in a manufacturing company and by a lecturer on technical management, the book outlines a concept of "total design," whereby technical issues of design and production are balanced by economic and marketing considerations. As an illustration of the system that the authors have devised, they present a detailed case study of the hypothetical British company, Omega Wire Forming, a large firm that had long prospered by supplying the automotive industry with springs and wire clips. With that industry depressed, however, Omega wished to broaden its product line so that it could move into new markets. The Board of Directors ordered the firm's design manage r to form a group consisting of members of the market research, production, sales, and design departments and to look into what new product could be made utilizing the company's experience in wire forming. There we re naturally guide lines on how much capital might be invested in new machinery and how much return on investment was expected, but otherwise the research group was unconstrained.

Within two weeks, the group identified wire paper clips as a viable new product. The decision was justified in part by data showing that in recent years the price of paper clips had risen almost three times as fast as the price of wire, that demand for the product was up, and that there appeared to be little customer loyalty to any particular brand. According to the group's analysis, if Omega could manufacture paper clips at three for a penny, it might expect to capture 10 percent of the domestic market, which was estimated to be 500 million paper clips per year. Furthermore, if the price could be lowered to four for a penny, Omega might expect to sell 80 million paper clips domestically and export another 20 million each year. Among the main anticipated costs was that of distribution.

Omega Wire Forming decided to get into the business of making paper clips, and the company's designers and engineers were instructed to focus their attention on improving the Gem paper clip and its method of manufacture. Since the standard-size Gem accounts for 90 percent of the market, its overall dimensions were believed to be fixed. However, if the leg s could be cut off shorter, up to 10 percent less total wire would be needed for each paper clip, thus reducing the cost of raw materials, which represents over half the manufacturing cost. A lighter paper clip would result, which would also reflect savings in shipping costs. A test engineer's determination that a paper clip with shorter legs resulted in onl y a 2 percent decrease in springiness or gripping strength clinched the decision.

Finally, at virtually no additional manufacturing cost, the inner loop of the paper clip could be given a slight be nd out of its plane, a competitive feature that had recently begun to appear on most competing British paper clips, thus reviving a feature that the inventor McGill had introduced almost a century earlier (see Fig. 2.6). Within a year of studying the problem, Omega Wire Forming was manufacturing modified Gem paper clips and was expecting to recover its investment costs in eighteen months. Thus are the economics of saving fractions of a penny on items that have potential sales in the hundreds of millions, if not billions worldwide.

Whether the Far East manufacturers of the new paper clips found lately in our stationery catalogs and supply cabinets followed so structured a total design process as that of Omega Wire Forming, the imported clips do embody some very si mi lar cost reduction features to give them an edge over more traditional domestic designs. It behooves those older manufacturers who do not wish to lose very much more of their accustomed market share to the newcomers on the shelf to look at the traditional designs with a critical eye to improving their usability and to educating paper clip users about the aesthetic, strength, and quality advantages that might be had for pennies more a box. The engineer, often acting as an inventor or designer, plays a central role in such considerations, whether the product be paper clips or computer chips. Indeed, the engineer is often the most severe critic of existing technology, and that is why things change over time. Curiously, however, where engineers find fault and see a need for improvement, others can sometimes find perfection.

FORM AND FUNCTION

The classic Gem paper clip is often held up by product designers as the epitome of modern manufactured articles. One design critic, praising elegant design solutions, has written: If all that survives of our fatally flawed civilization is the humble paper clip, archaeologists from some galaxy far, far away may give us more credit than we deserve. In our vast catalog of material innovation, no more perfectly conceived object exists. To watch a Middle Eastern bank teller bind together bank notes with a straight pin (a practice dating back to early Roman times) is to comprehend the paper clip's amazing grace.

And an architecture critic, marveling at "commonplace things of great design," clearly had the Gem in mind when he wrote:

Could there possibly be anything better than a paper clip to do the job that a paper clip does? The common paper clip is light, inexpensive, strong, easy to use, and quite good-looking. There is a neatness of line to it that could not violate the ethos of any purist. One could not really improve on the paper clip, and the innumerable attempts to try-such as awkward, larger plastic clips in various colors, or paper clips with square instead of rounded ends-only underscore the quality of the real things.

These excerpts are typical of the kind of praise heaped upon the Gem paper clip by those who look more at form than function. In their original context, such quotes are accompanied by illustrations of one or more Gems, but almost never clipping papers together. While the Gem may be a truly attractive and elegant object to look at when photographed in its own right, when applied as intended to a group of papers it takes on a less graceful appearance. The "bravura loop-within-a-loop design" is broken by the papers it is intended to hold, and the Gem can look curiously incomplete and misaligned, with its straight end not on target to meet the loop disappearing behind the sheets. When applied to more than a few sheets, the Gem can appear especially ungainly, twisted, and deformed.

Engineers and inventors are not so easily pleased with the object in the abstract. While they are not averse to designing things that look attractive, that is not the only criterion for elegance and beauty, which can only be skin deep. How a thing functions is often where engineers begin their quest, and no object that fails to function properly can be considered truly beautiful or perfected. To a host of inventors, the perfect paper clip remains an unfulfilled quest, as the steady stream of patents for new, improved paper clips attests. Even as the one-hundredth anniversary of the Gem approached, patent applications continued to be filed for still more improvements on the Gem and other paper clip designs.

Among the imperfect things about the Gem that many a recent inventor has discovered or rediscovered when reflecting upon how the "perfected" paper clip is used to clip papers together are the following: -->

- It goes on only one way. Half the time, the user has to turn the clip around before applying it.

- It does not just slip on. The user has first to spread the loops apart.

- It does not always stay on. The clip gets snagged on papers or other objects and gets pulled off.

- It tears the papers. The sharp ends of the clip dig into the papers when it is removed.

- It does not hold many papers well. The clip either twists badly out of shape or flies off the pile.

- It bulks up stacks of paper. A lot of file space can be taken up by paper clips.

When a new design removes one of these annoyances, it more likely than not fails to address some others or adds a new one of its own. This is what makes engineering and inventing so challenging. All design involves conflicting objectives and hence compromise, and the best designs will always be those that come up with the best compromise. Finding a way to bend a piece of wire into a form that satisfies each and every objective of a paper clip is no easy task, but that does not mean that people do not try.

A MODEL PAPER CLIP PATENT

Over the past century there have been several hundred patents issued specifically for bent wire paper clips, and each of them is a testament to its inventor's ability to find fault with existing paper clip designs, which more often than not are represented by the Gem. That the quest remains as challenging as ever can be demonstrated by looking at some paper clip patents from very recent years.

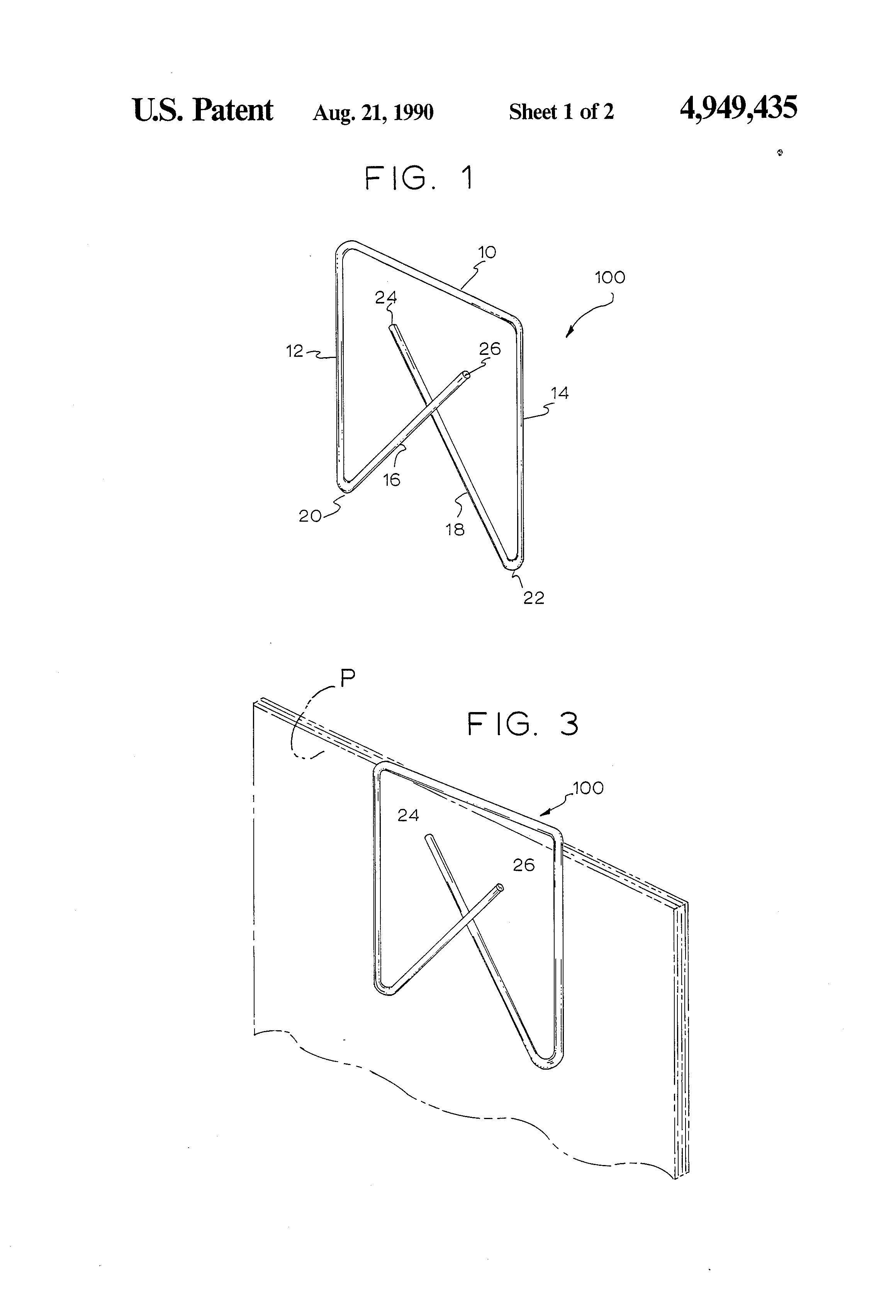

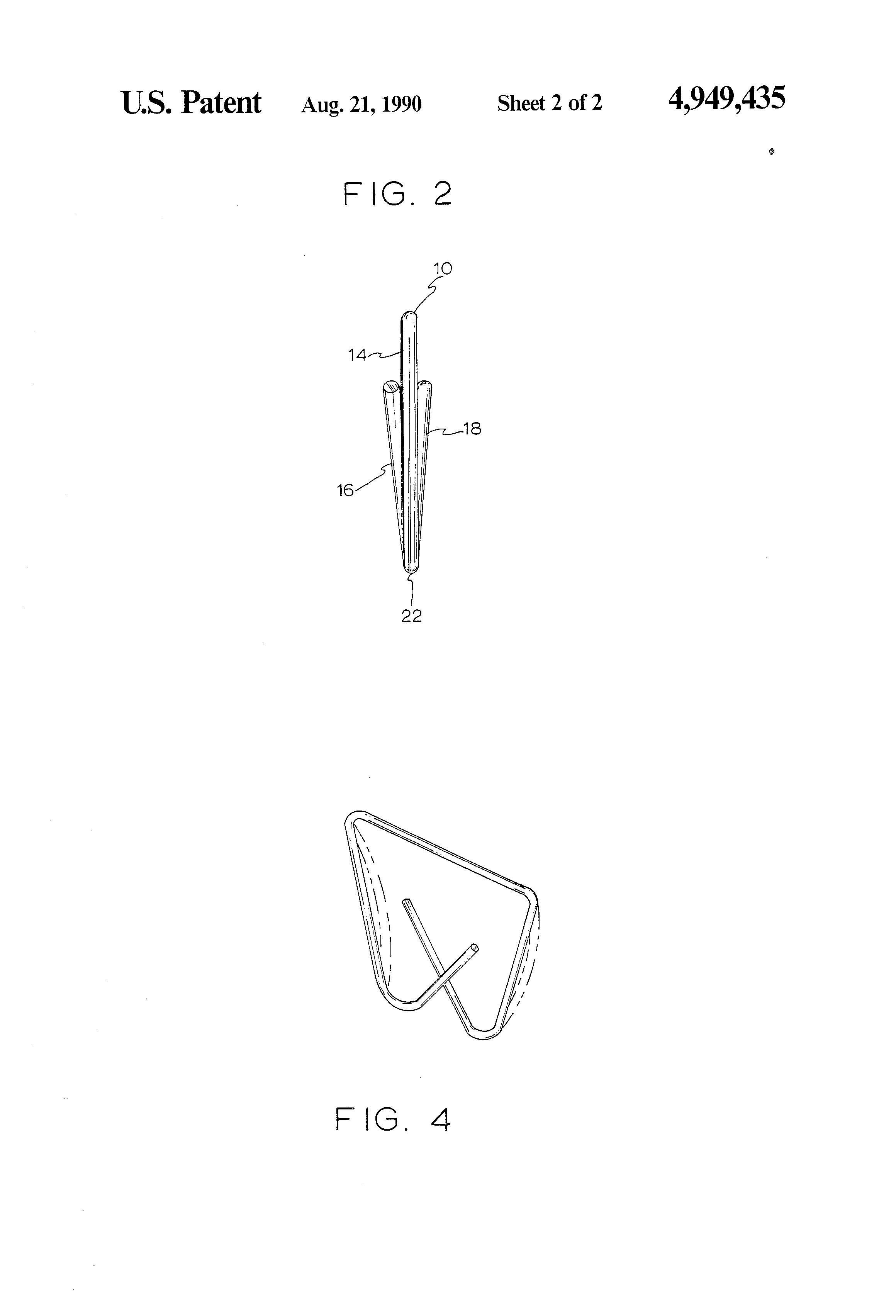

U.S. Patent No. 4,949,435 was issued on August 21, 1990, to Gary K. Michelson, a surgeon and inventor of medical devices from Venice, California. The cover page is in the format that has been followed since the early 1970s, when the U.S. patent and trademark laws were revised. This new format shows various things at a glance, including the patent number, name of the patent, name of the inventor, application filing date, which is not untypically a year or more before the patent is granted, and the date of the formal issuance of the patent, which by tradition will be at noon on a Tuesday. (In most countries, patent rights go to the person who files first. In the United States, the law holds that patent rights belong to the person who first came up with the idea, and this is why so many industrial and individual inventors scrupulously keep carefully dated notebooks of their ideas, experiments, and explorations.)

Also on the cover page are lists of Patent Office categories known as classes and fields involving the so-called prior art, or existing relevant technology, against which the novelty of the improvement is judged by the patent examiner. Related patents, both U.S. and foreign, are also listed on the cover page, as are other (non-patent) documents that might be relevant to the case. The cover sheet also shows the name of the patent examiner (a job that Albert Einstein held in Switzerland while he was formulating his theory of relativity) and the name of the inventor's patent attorney, agent, or firm. Finally, there is an abstract that briefly describes the invention, the number of claims (which appear on the last page of the patent and which spell out for what exactly the inventor has been granted a patent), and the number of drawing sheets (which can show the prior art as well as various views of the subject of the patent).

Drawings are a very important component of the patent, and an application can be delayed until drawings acceptable to the Patent Office are produced. The sheets of drawings follow the cover page, and in the case of Michelson's paper clip patent there are two sheets, or pages, of drawings, showing the paper clip from various points of view, with its various parts numbered for reference in the text of the patent. The drawing appearing on the cover page is one of those that appears on the inside sheets also. While patent drawings are very important in conveying the idea of the patent, these drawings do not always follow the best practices of engineering drafting, and so the device might not be easily understood from the patent drawings alone.

The textual part of the patent document begins with background to the invention, and the opening paragraphs of Michelson's patent are especially explicit in criticizing the prior art. Even though some of the language might be a bit excessive, as it is wont to be in patent applications, there should be little doubt that he is talking about the Gem:

Paper clips are generally used as expendable items to either temporarily attach papers or as indexing markers.

Use of the common paper clip presents a number of problems. In use, the two loops of the common paper clip must be digitally manipulated and manually spread so that papers can then be inserted between the loops. The common paper clip does not work well for any significant thickness of paper, being difficult to apply, and once applied is physically deformed, in the process, such that it cannot be reused without being deliberately and correctionally bent by the user. Further, when used with any significant thickness of paper, the loops of the common paper clip torque on their long axises [sic) such that the clip will not lie flat on the papers and will simultaneously protrude from the plane of the papers on either side. This also results in the sharp ends of the legs digging into the papers causing damage. More damage will usually occur during removal of the clip as the clip is dragged even deeper into the paper.

Also, because the loops of the paper clip are being spread apart, there is a tendency for the common paper clip to try to close by forcefully ejecting off of a thick group of papers, thereby presenting a very real threat to the user, who may be struck in the eye.

Michelson goes on in his patent with further criticism of the Gem when used as an indexing marker, such as it might be in marking the page of a book. The patent document then describes the new and improved paper clip, and Michelson is especially explicit in showing point by point how his paper clip is, "despite its relative apparent simplicity, a technological advancement and is superior to the prior art" with regard to his categories of capacity, reusability, ease of application, ability to lie flat, ease of removal, indexing features, safety, economics, and mailability.

The form of patents involves a lot of redundancy, and Michelson's patent is no exception. It goes on to state the object of the invention, which is essentially a rehashing of the description of the clip's advantages. Separate brief and detailed descriptions of the drawings follow, referring to the little numbers associated with the various parts of the device illustrated. Finally, the patent closes, as does every patent, with a legally crafted single long sentence, filling an entire paragraph, and prefaced by the phrase, "What is claimed is." It is this final section that is the ultimate focus of the patent examination, for it is what the applicant is allowed to claim or not for his or her invention that provides full protection or none. If none of the applicant's claims is allowed, then no patent can be issued... [End Excerpt]

References

- Invention by Design; How Engineers Get from Thought to Thing by Henry Petroski [1996.09.01 Harvard University Press; 4th edition]

- Gary K. Michelson | Michelson Patents

- Paper clip – Patent 4,949,435 | Michelson Patents

- Inside the Doctor's Cache: Tools for Better Back Surgery? [2005.05.18 Thomas M. Burton. The Wall Street Journal]

- INNOVATOR GETS AROUND PAPER CLIP'S CURVES [1995.08.20. The Wall Street Journal]

- Hey, Get a Grip! Your Basic Paper Clip is like a Mousetrap [1995-07-24. Amal Kumar Naj, Wall Street Journal | Michelson Medical Research Foundation]

Related Posts

In 1899 – William Middlebrook of Waterbury, Connecticut made the “Gem Clip” (Credit: Envato Images)

Illustration 1.) U.S. Patent No. 4949435A was issued on August 21, 1990 to Dr. Gary K. Michelson.

IIllustration 2.) U.S. Patent No. 4949435A Abstract: "An improved paper clip is disclosed consisting of a single piece of wire bent so as to have a straight top spine portion, two straight side leg portions substantially perpendicular to each end of the top spine portion and bent portions extending from, each side leg portion diagonally at approximately 45 degrees in the direction of the top spine portion. Each bent end portion extends from more than 1/2 the diagonal distance from the end of the side leg portion to the top spine portion."

![[Pg1] Innovation Lessons From a Billionaire | IP Watchdog](https://www.michelsonmedicalpatents.org/wp-content/uploads/2016/06-08-ipwatchdog-innovation-lessons-from-billionaire/Innovation-Lessons-From-a-Billionaire-IPWatchdog.com-_-Patents-Patent-Law_Page_1-260x185.jpg)

IP Watchdog

IP Watchdog

IP Watchdog

IP Watchdog

![Hey, Get a Grip! Your Basic Paper Clip is like a Mousetrap [1995-07-24. Amal Kumar Naj. The Wall Street Journal]](https://www.michelsonmedicalpatents.org/wp-content/uploads/1995/07-24-paper-clip-like-mousetrap-wsj/paperclip-wsj-260x185.png) Wall Street Journal

Wall Street Journal

![Hey, Get a Grip! Your Basic Paper Clip is like a Mousetrap [1995-07-24. Amal Kumar Naj. The Wall Street Journal]](https://www.michelsonmedicalpatents.org/wp-content/uploads/1995/07-24-paper-clip-like-mousetrap-wsj/paperclip-wsj-150x150.png) Wall Street Journal

Wall Street Journal![Medtronic Must Pay Inventor $159 Million [Barnaby J. Feder. 2014.09.29. New York Times]](https://www.michelsonmedicalpatents.org/wp-content/uploads/2004/10-29-medtronic-must-pay-inventor-$159-million-new-york-times/medtronic-must-pay-inventor-159-million-new-york-times-1-150x150.jpg) New York Times

New York Times